14.07.14

Sensors to determine embankment stability

The University of Southampton is working with Network Rail on a project to develop low-cost sensors for use in embankments to take soil readings that could predict earthwork failures. RTM heard more from Lecturer in Geotechnical Engineering Dr Joel Smethurst.

Network Rail wants to better understand the behaviour of embankments and cuttings during extremes of weather, such as flooding or drought. Many of these structures were built over 100 years ago using locally sourced materials and which, over the years, have seen substantial increases in train weight and speed.

Network Rail would like more early warning of problematic embankments, and is funding University of Southampton researchers to develop sensors that can be pushed into the soil, measure factors like water content, and ideally alert the right people if certain thresholds are triggered so remedial works can be prioritised.

The sensors themselves have been developed as part of another project – FUSE, the Floodplain Underground Sensor Network, funded by the Natural Environmental Research Council.

But the technology is extendable to take other kinds of readings, and Dr John Atkinson is involved with both projects.

His colleague Dr Joel Smethurst has been involved with the embankment stability work, a project running for one year that started on 1 October 2013, and told RTM: “It’s a fairly new technology, but we thought it would be a good idea if we could also try to apply it to other problems, including the problem that Network Rail has with some of its earthworks.

“It’s when embankments get very wet or very dry that there tends to be a particular problem for Network Rail. Dry conditions normally causes the clay earthworks, as commonly found here in the south-east of England, to shrink, and you get a very uneven track level and poor track quality, requiring speed restrictions.

“When the soil gets very wet, in terms of failing the embankment, it’s the water pressure that matters. That pressure, essentially, gives the soil a buoyancy, and causes it to become lighter, and that’s when it fails.

“We want to use the sensors to measure the water content of the soil, which can act as an indicator that there is a higher risk of failure, as a proxy for water pressure.”

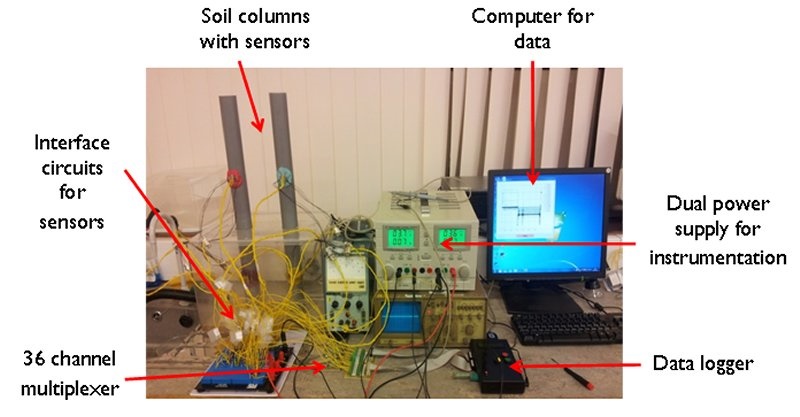

(Below: Laboratory experimental set-up)

Traditional methods of measuring water pressure involve drilling deep holes, which is costly and time-consuming. The sensors, by contrast, could be much closer to the surface and remain there.

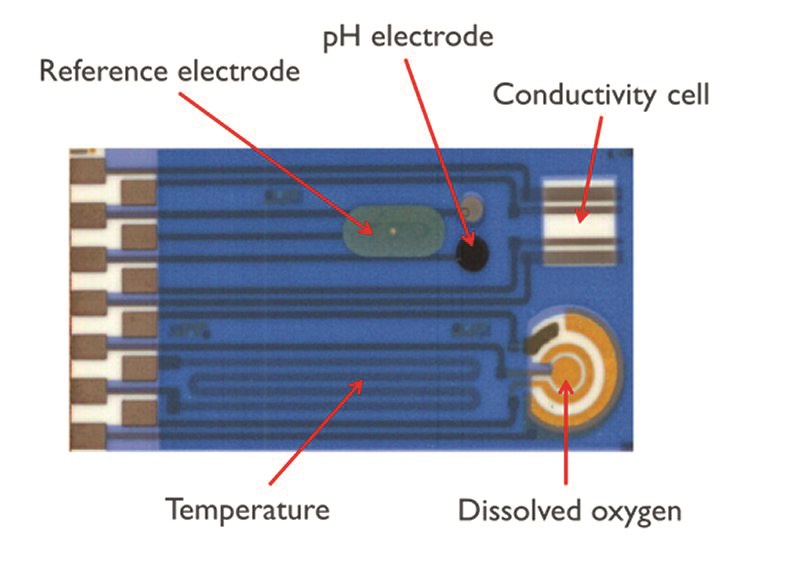

The sensors themselves are “not widely used at present” but have a lot of potential. Dr Smethurst described them by saying: "Layers of different metals and other materials are screen printed onto a small ceramic substrate to create the sensor. It’s a bit like a printed circuit board, in some respects. The advantage is that you can ‘screenprint’ the various layers on, so you have a series of ‘templates’ – and you then print the thin film layer of a particular pattern onto the plate. It’s pretty cheap, and you can print quite a large number of different sensors onto the same plate.”

Each sensor, about 10cm long and 5cm wide, would be connected to a wireless data logger.

(Below: Example of thick film sensor array from the FUSE project)

“You could plant a number of these sensors across an earthwork or a flood plain, and the sensors would relay the information. The intention is to get the cost of each sensor down, so you can install quite large numbers of them at a relatively high distribution.”

In lab experiments, they’ve been placed into cylindrical columns of soil that water and chemicals are pushed through, to test how the sensor responds to changes. For the FUSE project, that has included things like the pH value of the soil, but for embankment stability it’s all about water content.

Dr Smethurst said: “At this stage, it’s about understanding how the sensor functions and performs in practice. It would be desirable, once we’ve finished the work in the lab, to have a trial site fairly soon and have a go at installing some and see how that goes.”

Such trials could come next year in a successor phase of the project, he suggested.

But he added: “There are issues about how [the sensors] respond and how moisture content acts as a suitable proxy for measuring pressure. We’re thinking about how we might try to develop a similar film-printed sensor to measure pressure [directly], but it’s not easy.”

He envisions an alert system based on threshold changes within water content measured by a group of sensors, which would then flag a higher risk of slope failure or shrinkage problems.

Network Rail can then take appropriate action, whether by re-grading the slope angle, or installing better drainage, for example. This often entails a trench drain from the top to the bottom, filled with a more free-draining material than the clay, which tends to be the problem substance where earthworks are concerned.

The size of the sensor also depends on the material. The moisture content of coarse-grained soils can be difficult to measure using a small sensor, whereas for fine-grained clay soils, the sensor can be “reasonably small”, he said.

Dr Smethurst noted: “Many embankments were never built very well in the first place, and they’ve progressively aged.”

More extremes of weather as the climate changes will cause a “significant problem” and more embankment failures, he added.

Kevin Blacktop of Network Rail told us: "During Control Period 5 and beyond, Network Rail will be working with academic and commercial organisations to realise the Network Rail Technical Strategy and develop new technological approaches, such as this project with the University of Southampton, to enable us to manage our assets to support a high capacity and cost effective railway."

FOR MORE INFORMATION: www.tinyurl.com/RTM-embankments

Above, left: Dr Joel Smethurst, Lecturer in Geotechnical Engineering and MSc Civil Engineering Programme Coordinator. He is based at the Geomechanics Research Group, Faculty of Engineering and Environment, University of Southampton.

Right: Dr John Atkinson, Reader in Electromechanical Engineering, Faculty of Engineering and Environment, University of Southampton; and Programme Coordinator for the MSc course in Advanced Mechanical Engineering Systems.