16.01.14

Sleeper service

Source: Rail Technology Magazine Dec/Jan 2014

Network Rail requires up to a million concrete sleepers a year, but after the closure of one of the country’s two production facilities, it decided to seek a new contractor. RTM reports from the opening of the new sleeper factory at Doncaster, opened by transport secretary Patrick McLoughlin MP, and hears more from factory manager Peter Heubeck.

Network Rail’s new sleeper factory at Doncaster, managed by Trackwork Moll, can deliver 400,000 sleepers a year – and the indications so far are that they’ll definitely be needed.

The scale of Network Rail’s maintenance, renewals and enhancements programmes are such that its demand for high-quality concrete sleepers continues to rise, and in the coming years is likely to be anything from 700,000 up to a million annually.

While Network Rail also makes use of softwood, hardwood and metal sleepers on secondary and minor routes, its policy is to concentrate track renewals spend on the major inter-urban routes and on the best-quality concrete sleepers.

Trackwork Moll, the new joint venture of Trackwork of Doncaster and Leonhard Moll Betonwerke of Munich, which operates the facility on behalf of site owner Network Rail, is still in the testing and approvals process, but will begin supplying sleepers for the network by February.

The gleaming factory itself is ready, however, and was marked officially open by transport secretary Patrick McLoughlin MP at a short ceremony on 9 December.

‘Tremendous pressure’

After discussing the huge growth in passenger numbers on the railway in recent years, and in freight tonnage, McLoughlin told the assembled factory workers, officials and journalists: “The only trouble with growth like that is it does put tremendous pressure on the railways, on the rail operators, and on Network Rail.”

He spoke of a site visit to Belper early last year to see Network Rail’s high output ‘factory train’ Track Relaying System in action (RTM’s own detailed article and site visit to see the TRS2 system working can be found in our Dec 2012 / Jan 2013 edition, p28-29) and the huge amount of sleepers it needs to do its job.

In an interview with RTM after the ceremony, McLoughlin said: “It’s very impressive and it’s just another sign of the investment that’s going on into the railways.

“It is good news. The important thing is to make sure the sleepers we’re getting are up to a high standard and specification, and

quality. This is very welcome indeed. I’m very pleased to be here at Doncaster to see this new plant.”

He praised the factory workers and Network Rail itself, saying the general public sometimes forget how important the railway infrastructure is to the running of trains.

The factory

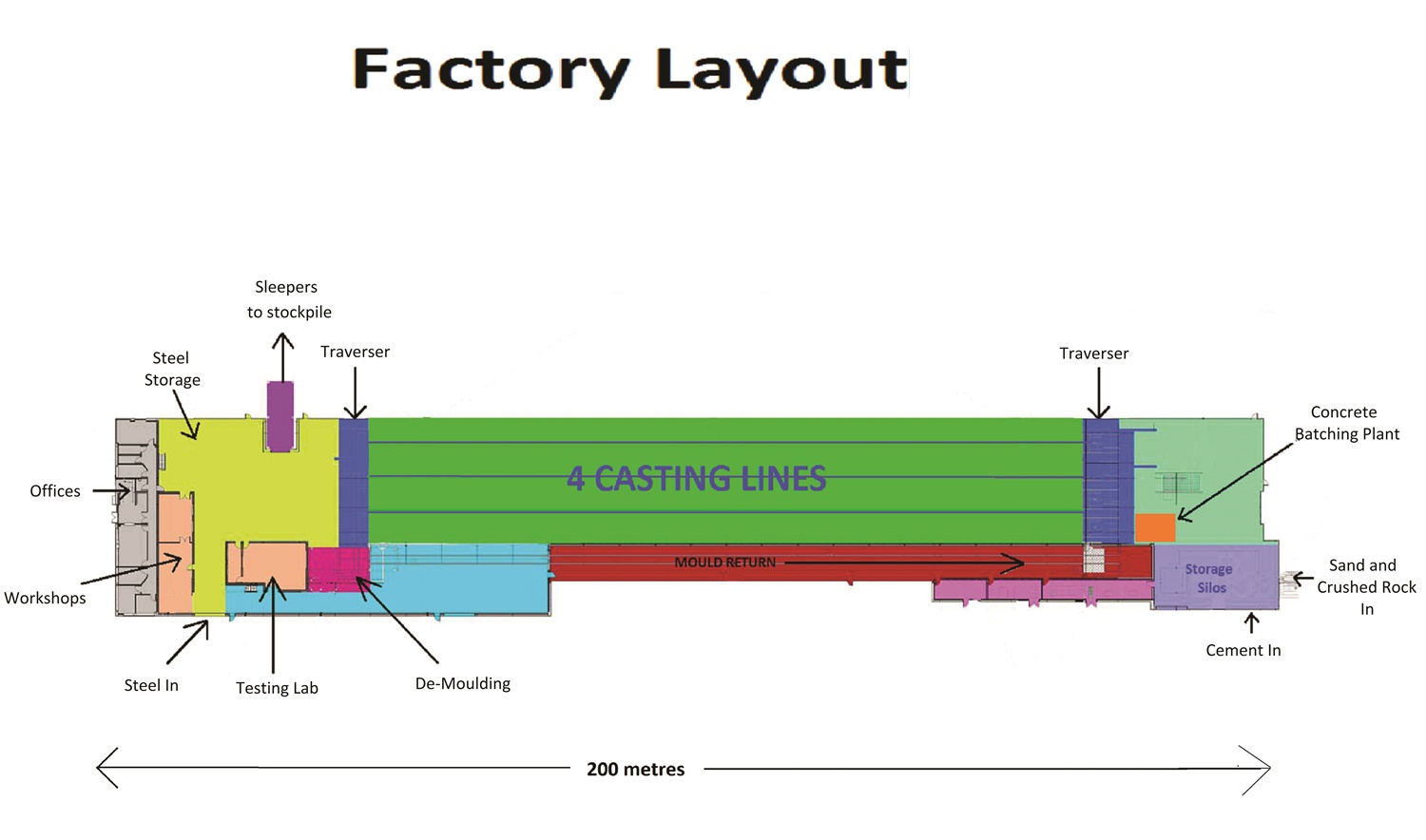

The new facility, located on the former Woodyard site near Ten Pound Walk in Doncaster, will employ around 45 people. Its general manager, Peter Heubeck, said the site clearance and construction cost around £6.5m, plus another £6m for the manufacturing equipment inside.

J F Finnegan of Sheffield was the design and build contractor on behalf of Trackwork Moll (itself building the factory on behalf of

Network Rail); Race Cottam Associates of Sheffield were project architects and the Doncaster office of Hannah Reed were the consulting civil engineers.

Heubeck told RTM that tests are still ongoing but the factory is now “almost” at the point of making perfect test sleepers. But it’s a long process, because the test sleepers need to attain their 28-day strength after casting, and then one of the tests – the cyclic loading test to simulate many thousands of passages of trains over a sleeper – takes a further three weeks.

Network Rail’s original announcements suggested the factory would be delivering sleepers for the network by spring 2013, but it won’t actually be until February 2014.

David Millar, projects manager in Network Rail NDS’s Enhancements team, told RTM: “Planning and getting the contracts agreed took longer than expected and, now that the construction is complete, the works to make sure that the sleepers are perfect is taking a little longer than expected. The factory is producing sleepers but is still a short time away from receiving product acceptance.”

Although the basic production method is tried-and-tested, the new factory automates many more processes to make it more efficient – meaning lower sleeper prices for Network Rail. There’s also been “real technical improvement” in two areas, Heubeck said – more accurate measuring of the tension load on each individual steel strand through the sleepers (there are six or eight tensioned strands depending on the sleeper type), and the new 3D measuring equipment in the factory’s own lab.

McLoughlin was shown how this equipment works, and Heubeck called it “so much more accurate than previous ways of doing it…it’s a real step forward.”

Steady-state production

Although Network Rail has suggested it will want every sleeper produced by the factory (about 400,000 a year), demand is certain to fluctuate. But the factory needs to maintain steady-state manufacturing to keep quality control high. So it has a huge stockyard able

to accommodate 90,000 manufactured sleepers to act as a ‘buffer’ between constant, predictable production and fluctuating real-world demand.

Heubeck said: “Although we can make just under 1,400 sleepers a day, our peak dispatch rate is probably three times that. We’ve got a massive gantry crane out in the stockyard, so not only are the sleepers cheaper, but distribution is easier and there’s very quick loading of wagons.”

He made the point that during the West Coast route modernisation in the mid-2000s, there were constraints on sleeper supplies, forcing Network Rail to spend a lot of money remotely stocking new sleepers next to where work was being done because sleepers couldn’t be dispatched quickly enough.

“With the dispatch rate we’ve got from this site, that should never be needed again,” he told us. The factory is working on an 11 days per fortnight production schedule.

Efficient handling

The factory also acts as a distribution hub, so the intention is that the sleepers will not need to be handled elsewhere between production and installation – with proper planning and logistics, they will be transferred directly to work sites.

In the case of the high output factory trains, their sleeper wagons will come directly to the factory and load up, and unload used sleepers. Used sleepers returned to Doncaster facility will remain Network Rail’s property, but Trackwork Moll will act as a kind of handling agent.

Some old sleepers will be sold on to farmers and the construction industry, others will be crushed at Network Rail’s own track materials recycling facility in Cambridgeshire, and roughly one in five will be able to be re-used elsewhere on the network.

Heubeck said the advantages for the high output operation of a quick turnaround in terms of loading and unloading sleepers outweighed any inefficiencies inherent in this double-handling of used sleepers.

Competing with Cemex

The factory’s sole client is Network Rail National Delivery Service (NDS). Heubeck joked: “The likelihood is that every sleeper we make, Network Rail will take – it’s a manufacturer’s dream come true!”

Since the closure of Tarmac’s factory, the only other place where sleeper production takes place is at Cemex at Washwood Heath, Birmingham.

Heubeck told RTM: “I know the guys at Cemex, they’re a fine team of people and a good company. Obviously they have got an older factory, which is less efficient than this one. They’ve also got a supply contract with Network Rail, and there’s a planning team in NDS who’ll decide what the optimum split of the market is. We have an advantage, as it’s quicker and easier to get sleepers from this site to almost anywhere on the network than from Washwood Heath. But I’m not running them down; they’re a good company, a good supplier, but Network Rail wants so many sleepers, we’re going to be busy and Cemex will be busy as well.”

Martin Elwood, director of Network Rail NDS, explained: “This factory is an important part of our strategy to protect and improve our supply chains for essential components on our railways and also to help reduce the cost of our track renewals.

“As well as re-introducing competition to the market, our investment in the factory when added to Trackwork Moll’s part-automated, modern production methods will all contribute to driving down costs.

“This site in Doncaster is ideal as it is central to the network and already has excellent rail links. The on-site laboratory and distribution centre also help to reduce transport costs.”

Sleeper types

There are two varieties of concrete sleeper produced by the Doncaster factory and used by Network Rail following standardisation aimed at improving efficiency.

G44 is the most common, and will form about 90% of the factory’s output. These sleepers, designed about 15 years ago, is suitable for 140mph line speeds and 30 metric tonne axle loads and so looks to the future. They are deep, and need only six strands, tensioned to a load of 7.5 metric tonnes, to give them the necessary strength.

EG47 sleepers are shallower and use less concrete, and so have eight strands through them. They are used on the third and fourth rail networks, and in areas where geography limits ballast depth.