01.01.15

‘We’re building two railways’

Source: Rail Technology Magazine Dec/Jan 2015

Crossrail is being built physically, but also digitally. Ross Dentten, asset information and configuration manager for the project, has done groundbreaking and industry-leading work to ensure the supply chain is ready for a ‘single source of truth’. RTM spoke to him.

Crossrail’s Ross Dentten uses a striking metaphor to describe how asset information handover is typically done between an infrastructure project’s designers or constructors and its operators – data is “thrown over the fence”.

Too often as a build nears completion, Dentten told us, asset information is patchy, poor quality and not always trustworthy. The operator and maintainer end up having to create mini-projects and do fresh surveys, “because they don’t really know what they’ve got, and they can’t make proper decisions”.

At the Solutions 2.0 conference in the USA in July 2014, Dentten outlined his view that despite the operate/maintain phase being 80-90% of a typical asset’s life, the asset information management process traditionally starts at the end of construction and beginning of the commissioning phase (with late, poor quality and inefficient results).

Crossrail set out to do things differently, and to make a good start right back during the design phase on its asset information management system (AIMS). In an interview with RTM, Dentten said: “If you leave it too late, when you get to the operational phase, there is no time to do it properly, the data isn’t trusted, and people start their own siloed approaches.”

Common data environment

Dentten joined the project in 2008 and has 25 years’ experience in the transport industry working for companies including Thales, Eurostar and South West Trains. He overhauled Crossrail’s document control system early in his time there, bringing in Enterprise Bridge (eB) instead (now owned by Bentley, although it wasn’t at the time). That was based on a business case with 80 requirements, which focused on having documents and assets ‘in the same place’. “That would cut down on integration required later on in the project,” he told us. “I went to the technical director, he approved it as the way forward, and we then got rid of the document control system we had in place and brought in eB.”

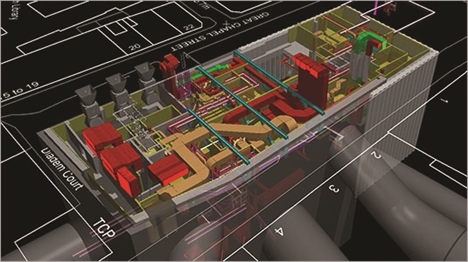

Bentley systems like ProjectWise were already in use as design tools, meaning Bentley’s purchase of eB proved beneficial for Crossrail. “We had all our information with one supplier, which was useful for us from an efficiency point of view,” Dentten said. Once configuration management was accomplished, eB was then also selected – after another business case with 300 requirements – for AIMS. “Now we’ve got documents and assets, with the right requirements, in one system. That is our ‘common data environment’,” Dentten said.

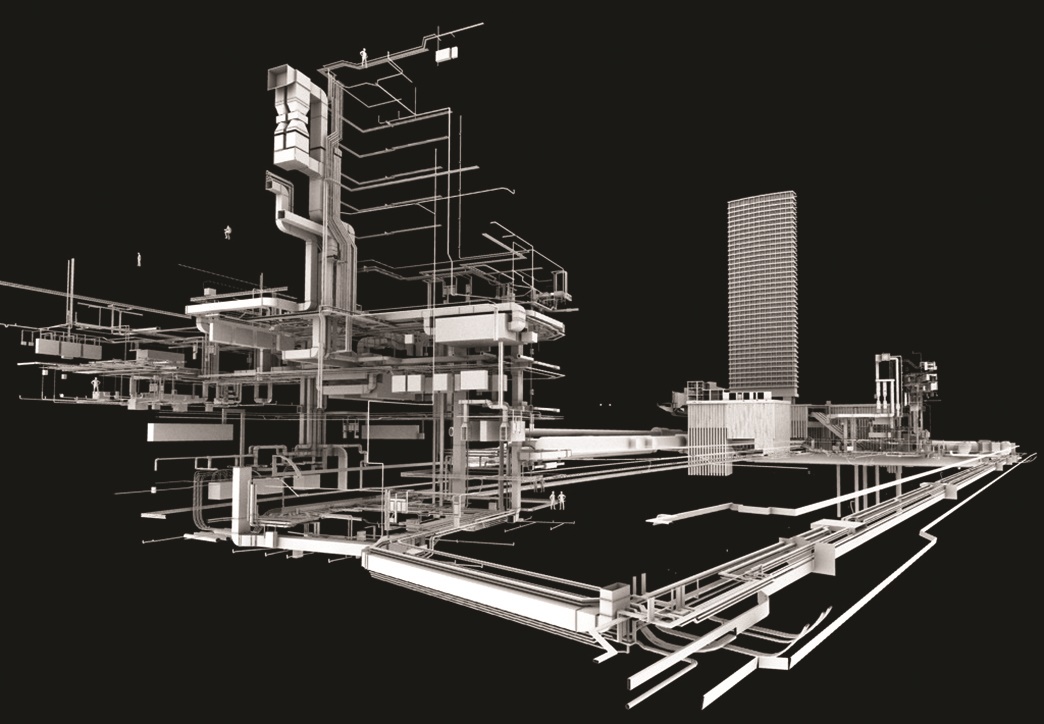

“We’re building two railways: virtual and physical. In theory, the virtual railway should lead, and the physical should follow. In reality, in the rail industry and other industries, that doesn’t always happen.

“With our ‘virtual railway’, we have documents that are related to assets. We have assets related to 3D models. We have dimensionally-accurate models that are then spatially shown in our GIS (geographic information system). Then we have more flexible visualisations, which also help us understand how to get from A to B.

“With the documents, assets, models, GIS, it’s all about linking the information and data between each component. That’s what the virtual world is about – the BIM world. BIM is not just about buildings, it’s really about assets and could be called ‘better information management’.”

Asset tags

Crossrail’s aim has been to define its asset requirements early on, with contractors procuring assets against the list of known requirements. Asset tags are vital for this, each coded by location, classification and function.

As a programme of individual projects across more than 40 construction sites, Crossrail has a lot of asset tags: an estimated 750,000 to a million. Dentten said: “So far we have 125,000 in the AIMS and the numbers are expected to rise dramatically in 2015 now the systems assets are being designed and introduced.”

This is a key enabler for Crossrail’s asset information strategy, alongside its asset data dictionary, asset information management plan, asset information standard, contract clauses, asset pointer, and asset information provision procedure. These are underpinned by the relevant standards, such as ISO 10007 for configuration management and ISO 55000 for asset management (replacing PAS55), plus BS1192.

He said: “Starting early was key. I would like to have started even earlier, but we’re certainly very well enabled now and we’ve got the right requirements in place for the contractors to deliver what we want.

“Having a common data environment, or single source of truth, isn’t just about being intelligent with your information: it also encourages people to collaborate in a sensible manner.”

Data on the front line

In our interview with Jon Kerbey elsewhere in this edition, we discuss the interface between the data environment and mobile devices on the front line, and how that project will cope as technology changes. Crossrail will face the same issues during its operational life, but the construction phase is already more than 60% complete, and tunnelling is just weeks from completion.

The project’s technical information, delivery and innovation departments have all helped ensure mobile data is used intelligently. Dentten explained: “We have a discrete team in the technical information department called the information applications team, which looks in more detail at some of the application capabilities we can enable from information. Obvious ones include the use of tablets on site, and we’ve had about 100 new tablets signed off recently. That means we can start using forms in an intelligent way, for example.

“There’s also initiatives like 4D virtual planning – particularly useful for the initial phases of the construction, but the systems people are particularly interested in it as well, to see how the equipment will be phased in.”

Trusting the data

Augmented reality is a fascinating hint of the possibilities unleashed when high-quality asset information, digital connectivity, mobile devices and geographic information come together. The idea is that a tablet or smartphone pointed at an asset out on the physical infrastructure, whether a section of track, cables buried behind a wall, or malfunctioning pump, can overlay the image with useful information drawn from the database. It can also allow the database to be updated as repairs or changes take place in the real world.

Dentten said: “It is a reality, and is very useful for certain situations. But the data still has to be correct behind it, and that’s the same with the visualisations. They can allow you to ‘look behind’ walls without actually taking the wall apart, for example. Now, that’s fine as long as you know for sure where the cabling is, and the system has been told ‘it’s here’, and it hasn’t been moved, and everyone has always followed all the processes.”

He hardly needed to say that unfortunately, in the real world, it is hard to guarantee that – especially if safety or performance could be compromised if the data about an asset is wrong or out-of-date.

Network Rail has been struggling with similar issues of safety and assurance when it comes to asset information. The director of its asset information division and ORBIS programme, Patrick Bossert, told us last year how plans for ‘self-service’ buried services enquiries had to be put on the backburner because the organisation wanted to ensure scrutiny by a competent buried services engineer was still part of the process. As Bossert told us: “It [would be] quite a big step to move to complete self-service, where we’re not providing a level of assurance. We certainly envisage buried services being digitised over the coming 24 months and included in the geographic information datasets that we make available. But clearly there’s a lot of safety risk associated with those services, and it’s not something we’d want to do without all right assurance processes in place.”

The next level

The as-yet-undefined BIM Level 3 is likely to move beyond traditional definitions of what an asset is, and begin to see anything that adds value as an asset: whether a physical object, a person’s skills, or a financial element.

“In essence BIM Level 3 is about moving from a common data environment into an open world, which is going to be challenging,” Dentten said. “Having open formats is definitely the way to go, but you’ve got software suppliers and vendors who have their own formats. That dialogue could take some time, unless it’s enforced by clients and the government. That’s not going to happen overnight.

“One of the key points of managing information in an effective manner is to have an object orientated relational database, which allows you to slice and dice the information in different ways. From that point of view, and if you look at ISO 55000, the definition of an asset is basically anything that gives value to the organisation. I suspect BIM Level 3 will be about involving people too. It’s something we’ll aspire to, definitely, though there has to be an element of realism with your ambition.

“Technology changes at an alarming rate, so you’ve got to make sure your data’s structured in an intelligent way, so it can be flexible enough to cope with whatever technology you throw at it.”

In our interview with Jon Kerbey, he outlines HS2’s supply chain concerns about standardised data formats, and its proposals to be more ‘agnostic’, integrating the data at a later stage in the process to help lower-tier suppliers.

Crossrail made a different decision. As Dentten explains it: “Crossrail made a very deliberate move to have one data format that all contractors have to comply to. That doesn’t mean they can’t use other software, to a point – although, really, that’s a bit futile, they may as well get used to the one we’re asking them to use.

“For us, it’s a sensible choice. It means we can co-ordinate the various types of 3D model we’ve got, be it mechanical, civil, architectural, etc. If we didn’t do that, we’d be in a right mess and we wouldn’t be able to assure anything in a correct manner. That may cause some problems for the contractor; but it’s the client setting the requirements.

“If we had an open format, it’d be a lot easier for everybody.”

(Above: Ross Dentten)

Tell us what you think – have your say below or email [email protected]