01.05.14

Automatic transmission

Source: Rail Technology Magazine Apr/May 2014

South West Trains is piloting a fuel saving measure for its Class 158 Sprinters when operating at low speeds. RTM talked to Christian Roth, fleet director for the South West Trains – Network Rail Alliance.

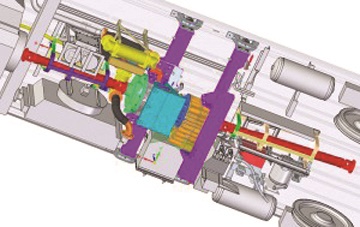

The Class 158/159 is a common sight across the UK rail network, in passenger service with seven different TOCs. The trains, built from 1989-1992 at BREL’s Derby Works, feature a Voith T211rz or T211rzz hydraulic transmission (and Gmeinder GM 190 final drive), but a modern mechanical gearbox is thought to offer better fuel economy on some routes, especially those with lots of stops.

Porterbrook, which owns a large number of the trains, has previously suggested that replacing the transmission with ZF technology would save “up to 10%” on fuel costs, with the only downside being more frequent maintenance overhauls, and the complexity of integrating the technology into trains more than 20 years old.

A trial is now underway on one of the South West Trains – Network Rail Alliance 158s which suggests that fuel savings will in fact be even higher than 10%.

The six to eight month trial, due to finish around July, shows savings “definitely above the 10% mark”, according to fleet director Christian Roth.

The operator has long been keen on using newer technology to cut fuel costs – RTM has previously covered its regenerative braking, train metering and variable stiffness bush (on the Desiros) projects.

Roth told us that alongside the carbon footprint benefits, there are real business and profitability benefits, especially with energy prices likely to go on rising.

He said the energy consumption on the train using the ZF mechanical gearbox (the Ecomat, as used on the Class 172s) depends on line of route, stopping pattern, and a number of other factors, but that the signs are all good.

He said: “It is technically complex to replace the existing hydrostatic gearbox design with a mechanical design. There are investment costs to do that kind of change on a piece of rolling stock.”

He hopes to use this trial to establish a business case with Porterbrook, because in a couple of years the old transmissions will have to be overhauled anyway. Offsetting investment costs in a replacement against those overhaul costs and the energy savings of a new transmission will make the business case easier to establish.

He called the Voith transmissions “the principal design of that time” – it’s the standard design for rail applications in the lower and middle performance range of rolling stock, used across Europe, he said. Higher performance diesels – HSTs and diesel locomotives, for example – usually have a generator and electrical traction motors instead.

But the ZF design is derived from HGV-type applications, he said, and made suitable for railway applications. “Automatic transmission and the associated power range and technology were not available when the 158s/159s were designed originally.”

The automatic transmission has five distinct gear ratios, so the fuel losses within the transmission at lower speeds are dramatically reduced.

Two of the transmissions are fitted under unit 158885 as part of the trial, which is gathering fuel efficiency data to be compared to another unmodified unit on the same diagrams and stopping patterns.

Roth said: “The basic results can be used for any kind of Sprinter or Super Sprinter or Turbostar. However, the specific amount of saving in terms of the percentage of fuel depends on the duty cycle of the rolling stock and the train service.

“Once our pilot is finished, we’ll know whether there’s a case to develop this further for other areas. The activity we are doing is very joined up with Porterbrook as the owner. There is sharing of information among the ROSCOs, the others are definitely aware.

“By July time, we’ll have a robust set of results regarding the fuel saving, and together with Porterbrook we’ll develop the business in autumn to make a decision on whether we go into fleet fitment or can’t make it work.

“It’s definitely encouraging, what we’ve seen so far. There is technical complexity – it’s not an easy project. But we’ve overcome a number of challenges already, so it’s looking quite promising.”

Vossloh Kiepe UK was commissioned by Porterbrook to test the feasibility of the retrofit in August 2012. Vossloh Kiepe UK’s engineering director Hugh Parker said at the time: “This trial is incredibly important to the industry as we have a legacy of regional diesel trains which will stay in service for some time to come.”

(Top image: Steve Hughes)

Tell us what you think – have your say below, or email us directly at [email protected]