30.09.15

Pageantry, excitement and a host of VIPs as Hitachi opens its new train factory

Source: RTM Oct/Nov 2015

RTM’s Luana Salles reports from the formal opening of Hitachi’s £82m new rail manufacturing facility in County Durham. The ceremony was exactly what you would expect from a company of the likes and size of Hitachi: aesthetically spectacular and technologically dramatic.

Hitachi’s new train manufacturing and assembly facility, which will build the 866 carriages of the new Class 800/801 InterCity Express Programme (IEP) fleet for the East Coast Main Line and Great Western Main Line, sits like an oasis in the middle of Newton Aycliffe. It is kempt and minimalistic from the outside, as all good brands should be, while discreetly sheltering 43,000m2 – as big as six football pitches, to contextualise – worth of state-of-the-art capabilities within it.

It will be capable of producing around 35 vehicles each month, the scope of which includes high-speed trains, commuter fleets and metro carriages for use nationally and in Europe. Manufacturing works will be tied together by its world-class research and development facility and 1.1km test track onsite. The modern Hitachi plant, its first in the UK, has completely transformed a patch of land that was basically farmland just two years ago.

Grand opening

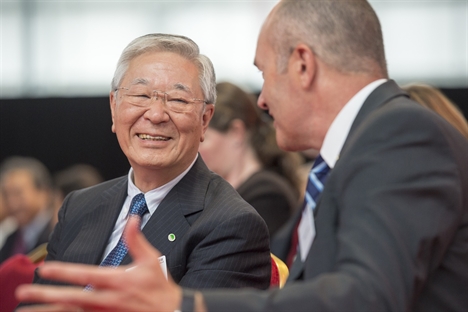

During its grand opening, attended by both the chancellor and the prime minister – “I wasn’t going to miss this for the world!” – more than 500 guests were treated to a continuous video feed boasting everything Hitachi is capable of doing. We watched the massive screen as the live feed showed aerial acrobats hanging from a gas balloon just outside the site, all while the transport secretary proudly cradled the facility’s opening plaque during formal pictures with the company’s global CEO, Hiroaki Nakanishi.

Rail leaders then proceeded to bury a sealed time capsule outside, containing a small model of the IEP train, digital photos of trains painted by local schoolchildren, time-lapse footage of the factory’s 20-month construction and a map of the site, all intended to be opened in 2040. The gesture was fitting for a company that looks at nothing but the future – and rightly reflects this in its creations. It was an emotional moment, and one that Hitachi hopes will prove that, even 25 years from now, the game-changing IEP train will still look and feel perfectly new.

Throughout the afternoon in the facility, guests were treated to a feast of entertainment, including a performance by young women from Urban Soul and an acrobatic shadow show from Tumbellina International. The sights and the accompanying music, always intense and loud, convinced you – if you already weren’t – that Hitachi isn’t only here to stay: it is intent on leading the way.

The unexplainably inspiring feeling running through the ceremony perfectly reflected what the facility itself was created to do: marry the best of British manufacturing to the reputable history of Japanese technology to give passengers the best of both worlds. “Today is a momentous occasion for Hitachi Rail, Newton Aycliffe and the British rail industry,” Nakanishi, evidently proud, told us. “We have brought train design and manufacturing back home to its birthplace in the north east.”

Appropriately, the facility’s neighbour, Heighington Crossing, once provided the backdrop to the introduction of George Stephenson’s Locomotion No. 1 on the rails of Stockton & Darlington Railway in 1895.

_edit.jpg)

Keeping it local

And indeed, the initiative to reminisce about and revive the north east’s manufacturing powers was sincere. Alistair Dormer, Hitachi’s global CEO for rail, said regional companies represented most of the supply chain, with 95% of the facility’s total spend hailing from within a 50-mile radius of the factory. More than 100 local staff had already been taken on with a plan to take 400 more by Easter, gradually employing more people thereafter.

Patrick McLoughlin had a lot to boast about. “Not only will these trains allow us to operate more services, with more seats, and faster journeys, the improvements will also bring great opportunities for growth, generating hundreds of jobs in the local area and thousands across the country within the supply chain,” the transport secretary told us. “The opening of this world-class facility is a prime example of the strength and opportunities of the Northern Powerhouse and is a welcome addition to the historical culture of rail excellence in this region.”

The Newton Aycliffe facility will also be used to build most of the 70 new AT200 commuter trains for ScotRail. The trains for Hitachi Rail Europe’s other recent big contract – the AT300s for routes from London to the far south west of England – will be built in Japan.

The big reveal

The event’s many speeches and presentations culminated in the theatrical – music blasting and curtains dropping – unveiling of the first fitted-out IEP train, brought to the UK especially for the ceremony after being built in Japan. The unit, in red and white livery, is the first of the 122 trains ordered to revolutionise travel between the capital, the north east and the south west.

They are scheduled to come into service on the Great Western Main Line from 2017 and on the East Coast Main Line a year later, with the full fleet operational by 2020 – all under a £5.7bn contract. The trains, built in five-car and nine-car combinations, will boast a mix of fully electric and bi-mode setups that will allow them to operate in parts of the Great Western network not yet electrified. As well as being integrated with the electrification programme and HS2, the IEP will include a series of new and refurbished depots across the two routes, including hubs in Swansea, London, Bristol and Doncaster.

‘Better than anything already in use’

One can hope that the depots, faring well and on budget (see the August/September edition of RTM for more), will set the standard for the rest of the fleet. Thankfully, this is a promise Hitachi intends to keep: “Our immediate goal is to deliver the Class 800/801 trains for the IEP on time, on budget and to exceed expectations,” Karen Boswell, managing director of Hitachi Rail Europe, commented. “These Hitachi trains will deliver new comfort and reliability to customers, improving seat capacity, luggage and storage – better than anything already in use.”

Elements of the Northern Powerhouse agenda may be beset by delays – but Hitachi’s new facility, set to reinvigorate train building in the UK, was right on time.