As part of the ongoing efforts to upgrade its Metro fleet, the Southeastern and Network Rail Alliance has enlisted Cordel to deliver precise data and imaging of all platforms on the metro network.

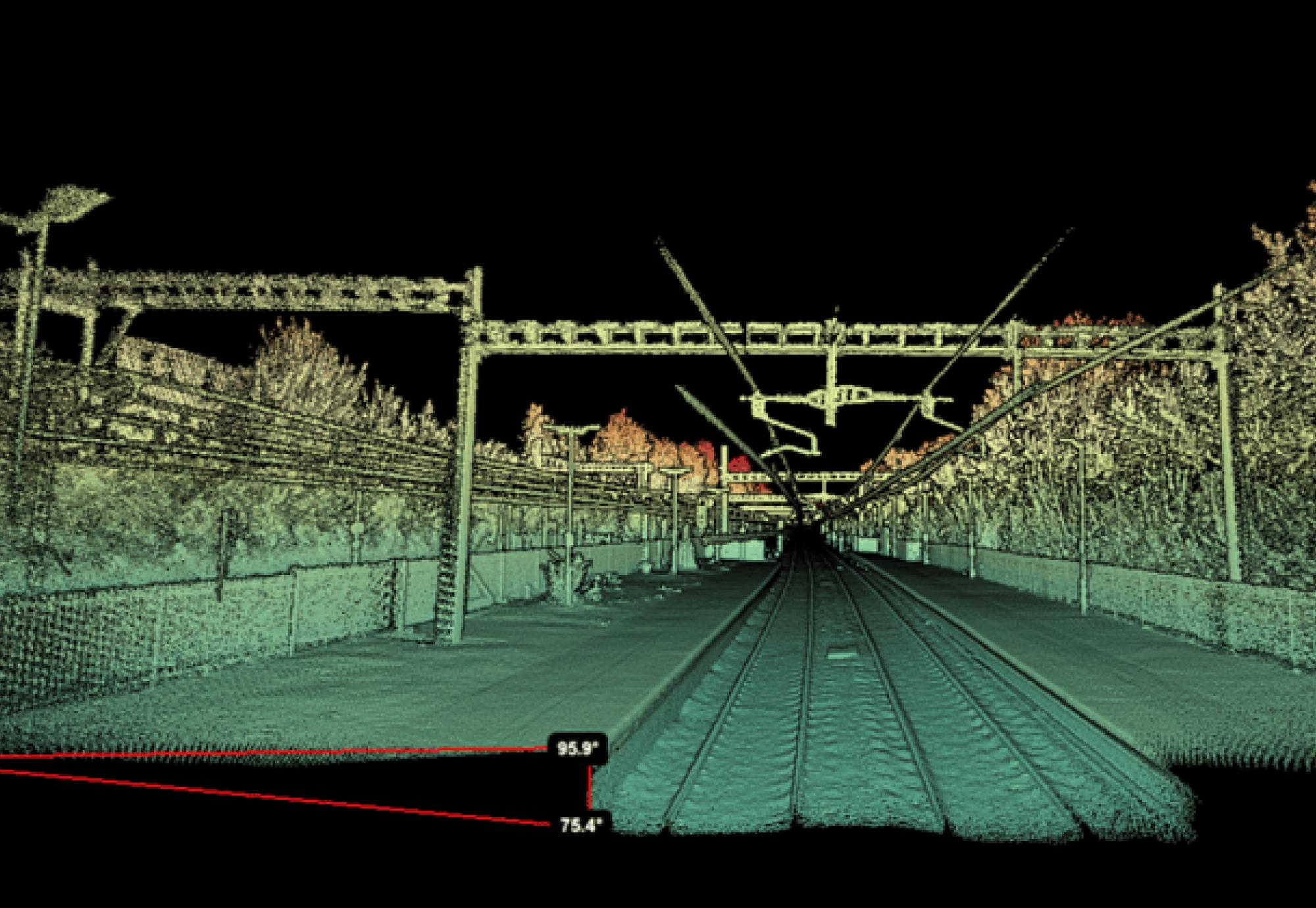

Cordel has equipped two Network Rail maintenance units with advanced sensor technology, utilising Light Detection and Ranging (LiDAR) and AI-processing services to create 3D models and obtain highly accurate measurements of all Southeastern metro station platforms.

Given that train station platforms across the country have been constructed and modified over many decades, their height, shape, and curvature vary significantly. This comprehensive analysis will provide detailed 3D modeling and dimensions of all the platforms that Southeastern’s potential new trains will serve.

This information will be instrumental in supporting manufacturers' design work to enhance unassisted boarding across the Southeastern Metro network. This initiative is a crucial part of Southeastern’s commitment to significantly improving capacity and accessibility by introducing new or upgraded trains on the Metro network.

The goal is to make boarding and alighting simpler and easier for customers in wheelchairs, those with mobility challenges, luggage, pushchairs, or any other obstacles, thereby fostering a more inclusive and accessible railway.

The LiDAR sensors have been installed on a pair of Network Rail maintenance trains, which will continuously collect data as they traverse the Southeastern network. This data will be analysed by Cordel and shared with Southeastern.

Mark Johnson, Engineering Director at Southeastern Railway, said:

“We want our upgraded Metro fleet to be a gamechanger for customers, not only in terms of performance and operating costs but also a major step forward for accessibility, too.

“However, we also know simply getting new trains won’t fix the historic issues we face across our railway.

“Our joint work with Network Rail and Cordel will, for the first time, provide highly accurate, 3D measurements of our platforms, including their height, curvature and gaps from trains. This information will be absolutely invaluable for manufacturers and suppliers to provide the best possible training for the Southeastern network.

“Work is already underway on our network and we look forward to the first data arriving in the coming weeks. “

Bob Coulson, Kent Route Infrastructure Director at Network Rail, said:

“Our partnership with Cordel.ai represents an important step towards creating a more accessible railway.

"By installing this new technology on our existing maintenance units we can build a truly accurate picture of our network across the Kent route, giving train manufacturers and suppliers the data they need to support our vision for a better, more reliable and sustainable railway”.

Image credit: Southeastern