The railway sector operates as the major form of public transport across the UK, seeing the services provided being utilised by thousands of people per day, relying on stable journeys for regular commutes or simply just leisurely travel. Due to the high amount of usage that these trains see on a daily basis, they require a large amount of general maintenance to ensure the continuous smooth operations.

There is often a need to replace key components that have faulted or worn down over time, meaning that mechanics must replace parts from their stock in storage. However, when they have no replacement stock readily available, these parts must be delivered to the railway provider from the manufacturer. This can often mean a delay for the required repair works, thus leading to a halt in operations within the train services of the affected route.

High-speed railways can reach upwards of 350km/h, which is great for quick and efficient travel needs, however this does create an issue when it comes to braking. each train carriage weighing more than 60 tons will produce huge inertia, which generates enormous kinetic energy, resulting in heating up of the brake discs due to friction while braking. Consequently, the brake pads and brake discs should not only withstand the high temperature of around 900 °C, but also ensure good performance at the same time.

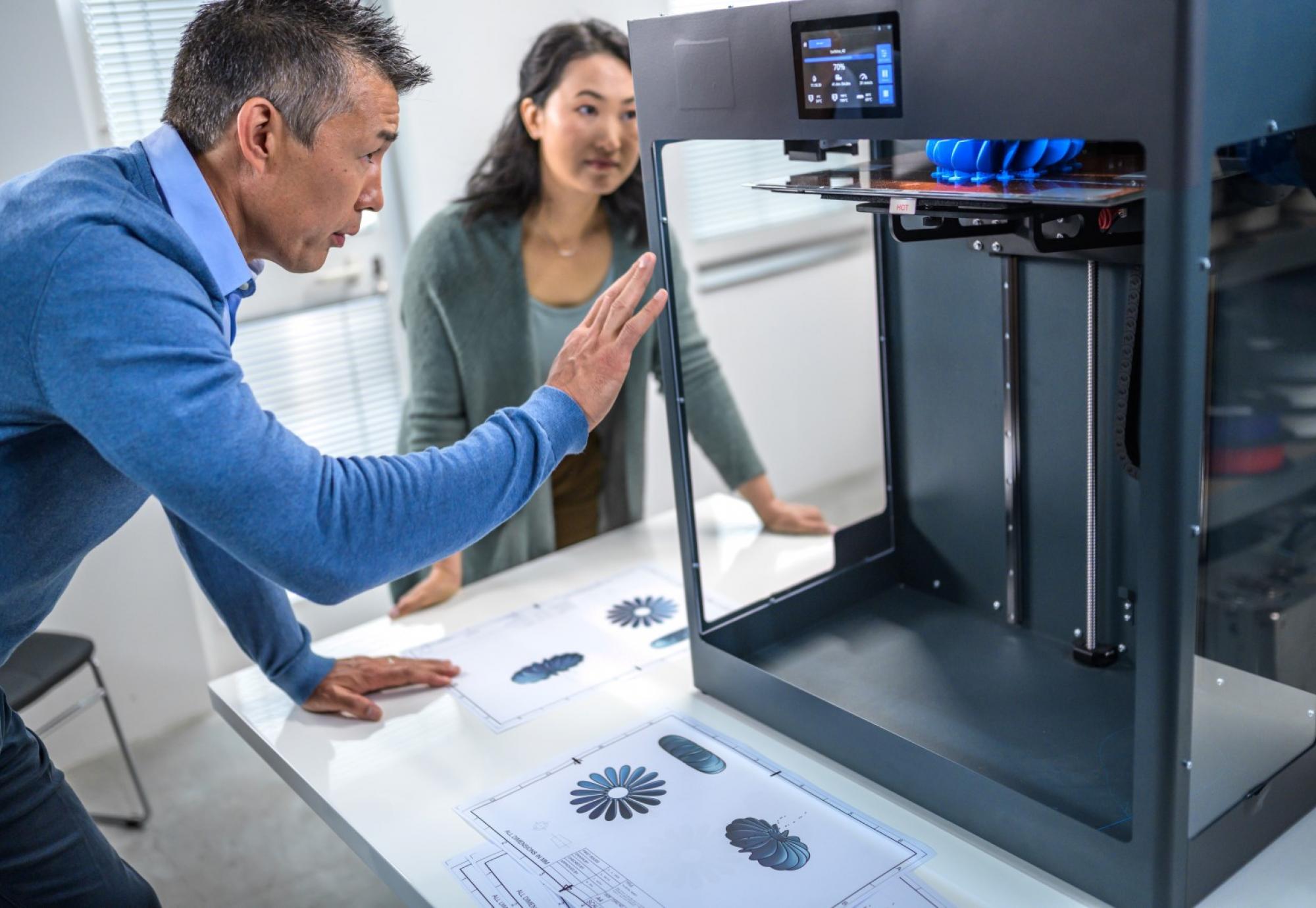

The R&D and production technology of high-speed railway pads and brake discs have gradually made breakthroughs in recent years. With the in-depth integration of metal 3D printing technology into the railway industry, metal 3D manufacturers have started to explore the application of metal 3D printing technology for performance improvements of brake pads and brake discs. Eplus3D, a Chinese AM manufacturer, also enters into railway industry with its large-format metal AM machines.

3D printing can be used in a plethora of new ways, not just for general rail maintenance, as seen with HS2s implementation of the cutting-edge technology, called ‘Printfrastructure’. London tunnels contractor SCS JV (Skanska Costain STRABAG Joint Venture) have been Printing concrete with computer operated robots, instead of transporting them as pre-cast slabs by road before being assembled and lowered into place by large cranes. This process has allowed major flexibility as it helps contractors to avoid the need to develop complicated and potentially expensive logistical plans.

Using a computer-controlled robot enables the reinforced concrete structures to be printed with a strengthening unique internal lattice structure, which not only significantly reduces the quantity of concrete required but also cuts waste.

This reduction to waste acts as one of, if not, the major benefits of 3D printings implementations within the sector. The use of this technology for mechanical parts such as brake disks will drastically improve rails ambitions of carbon neutrality, whilst helping to shorten production times and costs.

3D printing could be the future of construction within the rail industry, meaning companies throughout the sector should be keeping a close eye of the technologies development, seeking to implement it wherever possible.