09.02.16

AT200s: bringing Japanese expertise under British control

Source: RTM Feb/Mar 16

Ian McConnell, programmes & transformation director at ScotRail Alliance, and Jon Veitch, general manager in Scotland for Hitachi, speak to RTM’s Luana Salles about the ongoing task of building the new Class 385s and the importance of sharpening British skills abroad.

The benefits of ScotRail’s upcoming 70-train AT200 Class 385 fleet are clear: on one side, it will revolutionise travel for the thousands of daily commuters across Scotland’s central belt; on the other, it will greatly enhance domestic manufacturing skills by supporting hundreds of jobs in northern England.

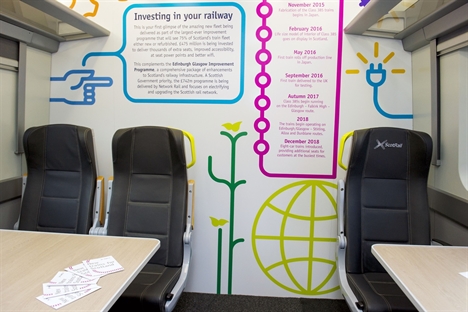

To ensure passengers are aware of these looming transformations, ScotRail, in partnership with the Scottish government, recently parked a life-size model of the interior of a Class 385 unit at Edinburgh Waverley. The model, which stayed open for public visits between February and March, showcased the train’s standard and first class saloon, including some of the actual seating and tables that will be used in the carriages once they come into service from autumn 2017.

Programmes & transformation director at ScotRail Alliance, Ian McConnell, told RTM the purpose of the model is two-fold: it served both as a way of engaging the public and stakeholders in order to shape and alter the fleet, and as a way of showing passengers that ongoing disruption to tunnels and services are just a means to a greener, faster and more reliable end.

Implementing customer feedback

According to McConnell, who was brought into the Network Rail-Abellio Alliance last year, feedback on the train has been largely positive, but a few changes are on the horizon. While these aren’t significant, they could include potential alterations to accommodate disabled passengers – such as adjusting the height of the pop-out and flip-down tables on the back of seats.

“We’ll all do our best to adapt those, to make sure that we take on board feedback from user groups and disability groups on things like that,” he said, noting, however, that the model is already entirely compliant with accessibility and PRM standards for reduced mobility. “In advance of the design stage, of course, we’ve engaged all the user groups on that front to make sure it’s compliant.”

Testing and building timeline

While seven of the 70 new trains were expected to be built in Hitachi’s Kasado factory in Japan before moving on to its Newton Aycliffe facility in the north east, Jon Veitch, the company’s general manager in Scotland, said this figure has now changed to six for “increased delivery”.

Speaking to RTM, Veitch also revealed that the first train is undergoing testing in the Japanese depot. “Bodyshells are now being produced day in and day out in Japan,” he said, shortly after a bodyshell was first previewed in late January.

The first bodyshell is expected to be shipped to the UK in April, he added, while the 64 remaining trains will start getting built domestically in late summer this year. The AT200 fleet will be manufactured at the north east plant for the time being, alongside the Intercity Express Programme Class 800/801 trains replacing high-speed units on the East Coast and Great Western main lines.

Honing domestic skills abroad

Making the case for a few trains to be built in Japan, Veitch underlined the importance of honing skills abroad before taking on this responsibility in the UK. But this does not mean that UK workers are missing out: “All the people that are employed in the Newton Aycliffe factory have spent considerable time honing their skills [in Japan] to make sure that we transfer the quality and the reputation of Japanese manufacturing over to ourselves,” he said, adding that this included shadowing Japanese workers as well as working hands-on on the shop floor.

“They’ve learnt the skills and the construction techniques of how they make these in Japan, and they’ve brought it over here. It’s very much about protecting our reputation, because the Hitachi and the Japanese philosophies are absolutely key and well known.”

Asked what element of this project most represented the Hitachi hallmark of Japanese technology, Veitch said: “For me, it’s the exhaustive testing and proving systems to ensure the reliability. Not everything is Japanese – obviously, there are local and European suppliers – but they’ve all had to meet the exhaustive performance characteristics we demand from Hitachi so that the brand is never damaged.”

On the train itself, he said the build quality “is second to none”. Much like the company’s flagship 225km/h Javelin Class 395s running for over seven years now on HS1, the AT200 model is designed to look just as good, and perform just as well, a decade from now.

Insofar as the interior layout, however, it’s all “very European”, Veitch noted: “We’ve agreed with the users and operator an exact layout, and we’ve just honed that and brought that into Japanese build. Some things are obviously peculiar to this train from the original mock-up, but it’s very much an agreed interior to meet the standards.”

Early tendering and Class 170 replacement

McConnell, who did not hesitate to call the upcoming trains “transformational” for Scotland, said one of the major reasons why Abellio won the franchise back in 2014 was because of its decision to kick-start a tendering process for the new fleet early. Indeed, just a day after FirstGroup lost the franchise to Abellio, the operator confirmed Hitachi was its preferred bidder for supplying the new and improved electric trains.

“We basically took a bit of a risk and went out to tender well in advance of the franchise being let, at our own risk and cost, and we were awarded the contract straight away,” he said. “Normally, to deliver new trains takes several years if you look at other examples around the country – but within 18 months or so of starting the contract, we’ll have these trains out on the ground, being tested and ready to start to go into service. The reason we were able to do that so quickly is because we went through this tender process very early.”

On the tendering process, McConnell said Hitachi stood out from other bidders because it was heavily investing in Europe, and in the UK in particular, at the time – including through ongoing works to build the Newton Aycliffe plant and the re-location of the global headquarters of its rail systems business to the UK in early 2014.

Once introduced from 2017 onwards, the Class 385s will replace the Class 170 diesel trains currently operating largely on the Edinburgh-Glasgow route in the central belt. “The line will be electrified – later this year, in fact – and then from that stage onwards, the 170s will gradually cease to be used, and the Class 385s will start to be introduced,” McConnell said. “Some of them are going back to the leasing company [Porterbrook], so a number of them we’re losing, but that was always part of the plan. We’ll still have some 170s running, so it’s not a complete replacement: we’re just shifting some things around.”

Part of the bigger picture

As well as the obvious headlines – faster trains, greener operation, 44% more capacity – McConnell emphasised that the particularities of the new fleet will help make a “massive difference” to Scottish commuters. For example, one of the new features ScotRail will be fitting in trains is a passenger counting system and application.

“It’s an app we’re developing which essentially tells people when they go on the train, which carriages are full, and which carriages are less full, in essentially live information,” he said.

“It’s still undecided exactly which supplier will produce the final version, but we’re working on it. If you commute day to day, then you tend to know which carriages are busier and which ones aren’t, but having that information at hand in an app will be invaluable.”

Yet more importantly, and perhaps evidently, the truly transformational element of the fleet will be triggered by the wider £742m Edinburgh Glasgow Improvement Programme, which will electrify the entirety of Scotland’s central belt as well as refurbish Glasgow Queen Street station – although McConnell argued ‘refurbish’ doesn’t quite do justice to the £112m project.

He added: “It all goes alongside lots of other things we’re doing in the franchise in other areas, such as station developments, other infrastructure projects, and other customer service initiatives. All those things put together are going to make a big difference.”

Tell us what you think – have your say below or email [email protected]